- Discover the high-quality 1616465600 2911001600 Compressor Oil Separator, designed to apply to Atlas Copco replacement machinery.

- Ensure optimal performance and efficiency with this essential component.

- Trust in the reliability and durability of this product to keep your equipment running smoothly.

- Upgrade your compressor system today with this top-of-the-line oil separator.

Reliable screw air compressor filters made in China

Reliable screw air compressor filters made in China!

Coolworks filter elements come in various models and are compatible with most brands.

.

✅Factory direct supply, better prices.

✅Professional team, serving you.

✅Fast delivery, worry-free and effortless.

.

Please provide the product part number or the air compressor model, and we will recommend suitable products for you.

Coolworks - Making filtration more efficient and simpler!

Hop on board the future of long-distance travel — the King Long 6112E awaits!

Hop on board the future of long-distance travel — the King Long 6112E awaits!

Sleek, smart, and all-electric, this 11-meter coach is built to go the distance—cleanly and comfortably.

Aerodynamically designed body? Check.

Double front windshields + LED headlights? You got it!

Easy maintenance? Absolutely.

Step inside and it only gets better:

Super comfy ergonomic seats

Spacious layout for stress-free travel

No emissions, no fuss—just smooth, stylish intercity travel.

The future of electric travel is here. Ready to ride?

Europe Standard Spray Booths Customized to Meet Your Business Needs

Our extensive product catalogue features a wide selection of spray booths, mainly manufactured in Europe Standard (CE Standard). Whether you operate in the automotive sector, run a small body shop, or require larger booths tailored to your specific industry and product dimensions, we provide solutions designed to meet your exact requirements, we have you covered.

Our spray booths will ensure a high quality coating, for that reason they can be equipped with vertical side wall or back airflow and with sectional or full-surface ventilation. These booths include a filtering system (plenum and floor) that will ensure a constant temperature and humidity inside.

In order to ensure efficiency, we offer you different heating options, from gas or diesel burners up to direct flame burners. We also install heat recovery systems, featuring a crossflow aluminium plate exchanger—to ensure optimal energy transfer between the exhaust and fresh air, leading to significant energy savings.

Choosing the right spray booth involves understanding your application, space limitations, finish quality requirements, and safety standards. With decades of manufacturing experience, Guangli offers a full range of paint booth solutions that meet international standards and deliver reliable, high-performance results.

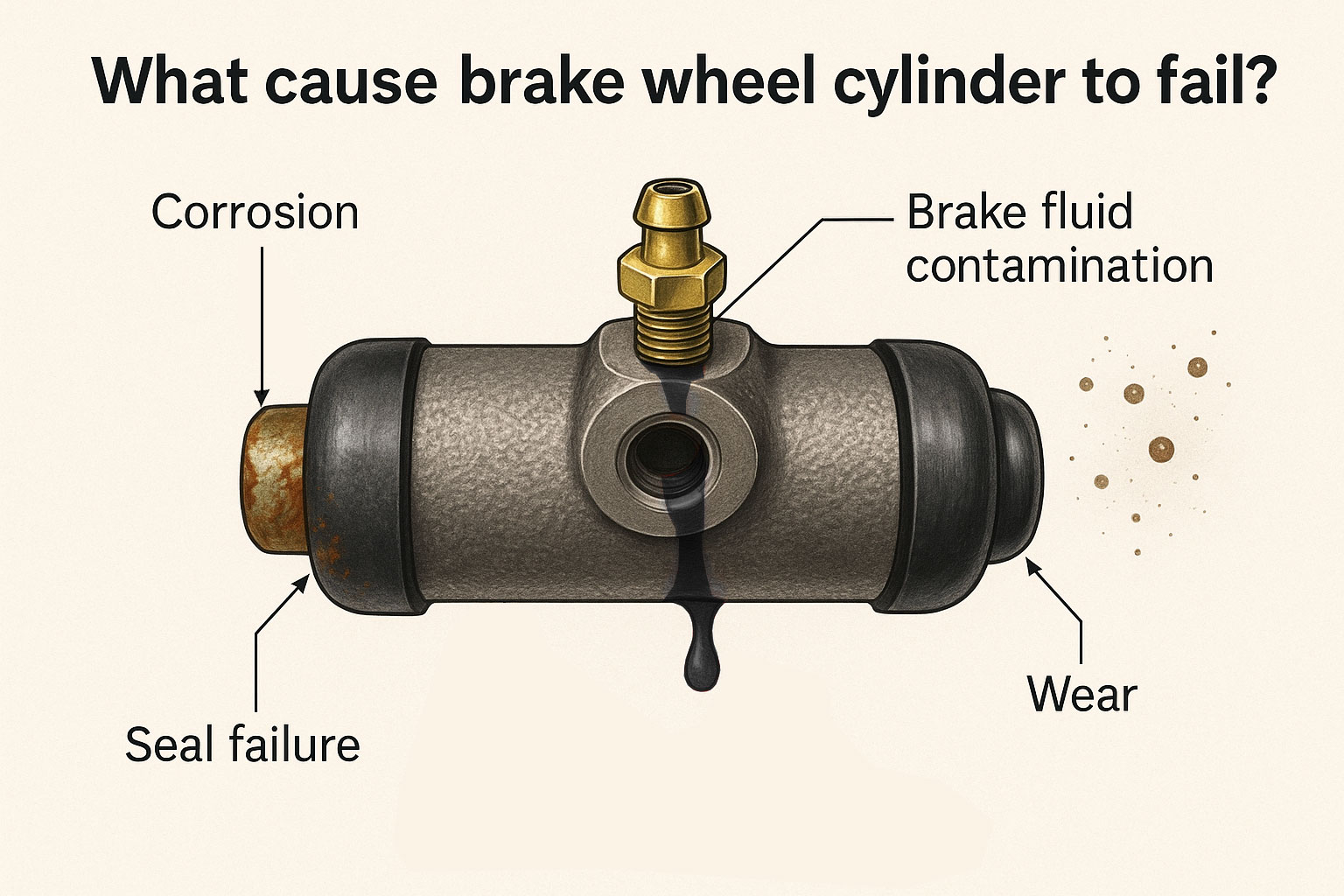

What cause brake wheel cylinder to fail?

The reasons for the failure of the brake cylinder can be summarized into the following categories, covering oil quality, component aging, lack of maintenance, mechanical failure and other factors:

Oil quality problems

Brake fluid contamination or deterioration: The oil is too dirty, causing impurities to block the oil pipe, increasing the pressure of the master cylinder and accelerating the wear of the drum brake wheel cylinder; deteriorated oil corrodes the seals (such as the leather cup), causing seal failure and oil pressure leakage.

Brake fluid ingress or air mixing: Water causes rust inside the cylinder, and air causes a decrease in hydraulic transmission efficiency, both of which will lead to weakened or failed braking force.

Component aging and quality problems

Seal damage: The piston cup of the cylinder is aging, cracked or the seal ring is damaged, resulting in brake fluid leakage and oil pressure cannot be maintained.

Piston stuck or rusted: The long-term failure to replace the brake oil causes the piston of the cylinder to rust and get stuck, unable to return to its position normally, causing dragging or locking.

Quality defects of the slave cylinder: such as poor material or insufficient processing accuracy (such as mismatch between the piston and the cylinder), often occur in low-grade products. Choosing a reliable China supplier brake wheel cylinder can reduce the risk of premature failure.

Improper maintenance

Exceeding the limit of brake pads/discs: Brake pads worn to the limit or deformed brake discs increase the workload of the slave cylinder, and long-term overpressure operation causes damage to it.

Brake fluid is not replaced regularly: Brake fluid that exceeds the replacement cycle (usually 2 years) has strong hygroscopicity and is prone to corrosion and bubbles.

Improper free travel adjustment: The pedal free travel is too small or there is no travel, and continuous pressure on the slave cylinder causes overheating and damage.

Mechanical damage and blockage

Oil pipe rupture or joint leakage: Hydraulic line leakage directly leads to insufficient pressure in the slave cylinder. Compensation hole/vent blockage: The blockage of the compensation hole of the master pump affects the flow of oil, resulting in interruption of oil supply to the slave cylinder.

External pollution and corrosion

Brake dust or muddy water intrusion into the guide pin or piston of the wheel cylinder aggravates wear and corrosion, affecting the flexibility of piston movement.

Electrical failure (partial electronic wheel cylinder)

Abnormal voltage (too high/too low) may cause the motor of the electronic wheel cylinder to burn out or the control module to fail.

Brake wheel cylinder failure is mostly caused by improper oil management (the highest proportion), sealing system collapse, and maintenance deficiency, and a few involve manufacturing defects or external pollution. For vehicle owners looking for durability and affordability, selecting products with factory price brake wheel cylinder options from trusted manufacturers is essential. Regular replacement of brake fluid (every 2 years or 40,000 kilometers), timely inspection of brake pad/disc wear, and avoidance of inferior oil products are the key to prevention.

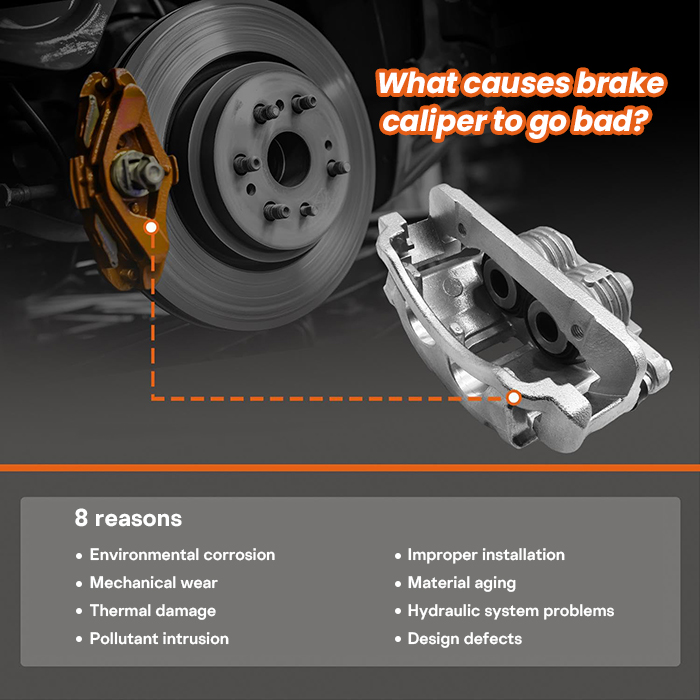

What causes brake caliper to go bad?

What causes brake caliper to go bad?

Introduction to the working principle of calipers

Car calipers are the core components of disc brake caliper. They use hydraulic pressure to push the piston to squeeze the brake pads and generate braking force by friction with the brake disc. A healthy caliper should have good sealing, smooth piston movement, and stable structural strength.

Main causes and mechanisms of damage

-

Environmental corrosion

Salt spray erosion: Salt in the air in coastal areas accelerates metal oxidation

De-icing agent corrosion: Chemical corrosion caused by salting roads in winter

Typical case: The rust rate of vehicle calipers in northern regions is 40% higher than that in the south -

Mechanical wear

Wear of piston seal ring leads to hydraulic oil leakage

Abnormal wear caused by insufficient lubrication of guide pins

Direct friction of metal backing plate with caliper after excessive wear of brake pads -

Thermal damage

Continuous downhill braking produces high temperature above 300℃

Thermal deformation causes piston jamming

High temperature causes brake fluid to vaporize and form air blockage -

Pollutant intrusion

Sediment enters piston cavity and wears seals

Road antifreeze penetrates and corrodes metal

Water intrusion causes piston rust -

Improper installation

Guide pin torque does not meet the standard (standard value is usually 35–45 N·m)

Wrong use of piston return tool

Brake pads are not installed in place -

Material aging

Rubber seals age naturally in 5–7 years

Metal fatigue causes structural strength to decrease

Dust cover cracks and loses its protective function -

Hydraulic system problems

Brake fluid contamination accelerates rubber parts degradation

Hydraulic pipeline blockage leads to abnormal pressure

Master cylinder failure causes hydraulic shock -

Design defects

Irrational heat dissipation structure

Improper material selection

Inadequate dustproof design

Prevention and maintenance suggestions

Regular inspection

Check piston movement every 10,000 kilometers

Check whether the dust cover is damaged

Measure the remaining thickness of the brake pad

Proper maintenance

Replace brake fluid every 2 years

Use special grease to maintain guide pins

Avoid high-pressure water gun direct spraying calipers when washing the car

Driving habits

Avoid long-term continuous braking

Lightly press the brake after wading to remove water

Do not wash the car immediately after parking

Maintenance precautions

Use original disc brake calipers or high-quality aftermarket brake caliper

Strictly install according to torque requirements

Check the caliper status when replacing brake pads—this is often a good time to consider brake caliper replacement if significant wear or damage is detected.

Caliper damage is often the result of multiple factors. By understanding these reasons, car owners can take targeted preventive measures to extend the service life of the caliper and ensure driving safety. When the above warning signals appear, it is recommended to go to a professional maintenance point for inspection immediately.

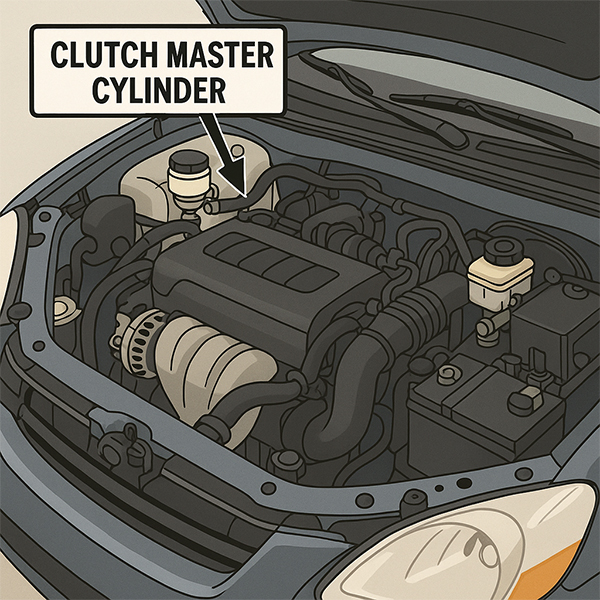

Where is the clutch master cylinder located?

As the core control component of the hydraulic clutch system, the physical location of the clutch master cylinder is directly related to the driver's control experience. It is usually installed at the end of the clutch pedal, fixed to the pedal bracket by bolts, and the push rod is mechanically linked to the pedal. This design ensures that the driver's pedaling action can be instantly converted into a hydraulic signal, thereby controlling the separation and engagement of the clutch. KOMP, a leading Chinese clutch and brake pump manufacturer, specializes in the development of high quality clutch master cylinder solutions that ensure long-term reliability and precise control.

1. Positioning and Structural Design

Precise position: The master cylinder is close to the rear of the clutch pedal. Some models need to disassemble the trim panel or battery bracket under the instrument panel to observe it.

Connection relationship: It is connected to the clutch slave cylinder (located in the gearbox housing) through a high-pressure oil pipe to form a closed-loop hydraulic system.

Error-proof design: The master cylinder piston has a built-in limit screw to prevent rotation, and the oil inlet valve ensures stable flow of oil by balancing the pressure difference.

2. Working Principle and Hydraulic Transmission

When the driver steps on the pedal:

The pedal pushes the master pump push rod, the piston moves left to close the oil inlet valve, and the oil chamber pressure increases;

The high-pressure oil is transmitted to the slave pump through the oil pipe, pushing the release bearing to disengage the clutch;

After releasing the pedal, the piston resets under the action of the return spring, and the oil flows back to the oil reservoir.

In this process, the pumping oil volume of the master pump directly affects the push rod stroke of the slave pump. The piston thickness and cavity volume of different models need to be accurately matched. Choosing a reliable wholesale clutch master cylinder ensures that these precise specifications are met for optimal performance.

3. Maintenance and Fault Response

Replacement cycle: It is recommended to check every 2 years or 60,000 kilometers. If there is oil leakage or abnormal pedal rebound, it needs to be replaced immediately.

Operation points:

When disassembling, the oil pipe and pedal push rod must be disconnected first, and attention should be paid to protecting the seals;

After installing the new pump, the hydraulic system air must be emptied to avoid "half-linkage" failure.

4. Common Problems and Optimization Suggestions

Risk of oil leakage: The main reason is the aging of the oil seal after long-term use. It is more common in Focus and other models after 100,000 kilometers;

Performance optimization: Upgrading to a new master cylinder (such as a thickened piston design) can reduce the pedal force;

DIY tips: Non-professionals are advised to avoid self-disassembly and assembly, as the screws in the dashboard are difficult to operate.

Considering the clutch master cylinder price is also essential when choosing between repair and replacement. KOMP offers cost-effective options without compromising quality, making it a trusted partner for both automotive professionals and distributors.

Changan NEVO Q05 A Compact Electric SUV Built for the Future

🚗 Changan NEVO Q05: A Compact Electric SUV Built for the Future

In a world rapidly shifting toward intelligent and eco-friendly transportation, the Changan NEVO Q05 delivers a perfect balance of innovation, performance, and practicality. As one of Changan’s newest entries in the new energy lineup, the Q05 offers a premium driving experience in a compact and affordable electric SUV format — ideal for city commuters, families, and overseas buyers alike.

🌟 Driving Experience & Highlights

From the first time you step inside the NEVO Q05, it’s clear this is no ordinary compact SUV:

Smooth Electric Drive: The pure electric powertrain provides instant acceleration, responsive handling, and whisper-quiet operation — perfect for urban traffic and daily commutes.

Comfortable Ride: Equipped with independent suspension and a refined chassis, the Q05 absorbs bumps effortlessly, offering a smooth and confident driving feel.

Agile and Easy to Park: Its compact size makes it maneuverable in tight city spaces without sacrificing cabin comfort or storage.

Range and Efficiency: With a competitive electric range, the Q05 is ready for your daily adventures with minimal charging interruptions.

Whether you’re navigating through traffic or cruising on an open road, the NEVO Q05 provides an enjoyable and intelligent driving experience.

🧠 Smart Technology & Interior

Digital Cockpit: Features a wide digital dashboard and central touchscreen with real-time EV data, navigation, and entertainment.

Advanced Safety Features: Includes automatic emergency braking, lane departure warning, and blind-spot monitoring.

Comfort-First Design: Soft-touch materials, ample headroom and legroom, ergonomic seats, and a quiet cabin.

Mobile Connectivity: Supports smartphone integration, voice control, and over-the-air software updates for a connected experience.

🌍 About Us — Nanjing Kaitong Automobile Service Co., Ltd.

With over 10 years of experience in global auto trade, Nanjing Kaitong Automobile Service Co., Ltd. is a trusted Chinese exporter of:

✅ New energy vehicles (EVs, hybrids)

✅ Traditional fuel cars and pickup trucks

✅ Auto parts and exterior accessories

✅ Full export services including logistics, documentation, and after-sales support

We’ve served clients in more than 50 countries with a commitment to quality, reliability, and customer satisfaction. Our strong supply chain and multilingual team ensure smooth and efficient vehicle exports worldwide.

Looking to import the Changan NEVO Q05 or other Chinese EVs? We’re here to make it easy and affordable.

📩 Send Your Inquiry Today

Whether you're a dealership owner, fleet manager, or just a smart buyer looking for a high-quality EV, the NEVO Q05 is a smart investment.

Contact us today for the latest price, shipping details, and purchase options!

Geely Lynk & Co 900 Redefining Luxury and Performance in a Flagship Sedan

🚗 Geely Lynk & Co 900: Redefining Luxury and Performance in a Flagship Sedan

As the flagship luxury sedan from Lynk & Co — a joint venture between Geely and Volvo — the Lynk & Co 900 combines European refinement with Chinese innovation. With its elegant design, state-of-the-art technology, and exhilarating performance, the 900 model is poised to challenge traditional luxury brands on a global scale.

🌟 Driving Experience & Highlights

Driving the Lynk & Co 900 is nothing short of thrilling:

Powerful Turbocharged Engine: Whether you're cruising the highway or navigating city streets, the engine delivers smooth, high-output acceleration with minimal lag.

Refined Chassis & Suspension: Built on a premium architecture with Volvo influence, the ride is balanced and composed, even on imperfect roads.

Quiet, Luxurious Cabin: Double-glazed windows and soundproofing materials make for a serene ride. The cabin is wrapped in premium leather and accented with metal trims.

Intelligent Drive Assist: Adaptive cruise control, lane centering, and automatic parking make every journey stress-free and futuristic.

This is not just a car; it's a lifestyle statement — aimed at those who value style, technology, and performance in one seamless package.

🧠 Design & Interior Technology

Panoramic Infotainment: A large central touchscreen with smartphone integration, voice commands, and 5G connectivity brings the digital world to your dashboard.

Ambient Interior Lighting: Customize your mood with dynamic lighting options throughout the cabin.

Massage & Heated Seats: First-class comfort for long-distance drives.

Spacious Rear Seating: Executive-level legroom and headroom, ideal for both owners and chauffeurs.

🌍 About Us — Nanjing Kaitong Automobile Service Co., Ltd.

We are a professional automobile and auto parts exporter based in China, with over 10 years of experience serving global clients.

Our services include:

✅ Export of electric, hybrid, and fuel vehicles

✅ Full range of pickup trucks, SUVs, and sedans

✅ Auto parts, body kits, and accessories

✅ One-stop export service including inspection, customs, and shipping

We are proud to deliver trust, transparency, and quality to customers across Asia, the Middle East, Africa, Europe, and Latin America.

Whether you're a car dealer, importer, or distributor, we’re your most reliable partner for sourcing Chinese vehicles like the Lynk & Co 900.

📩 Ready to Own a Lynk & Co 900?

The Geely Lynk & Co 900 is not only about luxury — it’s about making a statement.

Contact us today for the latest pricing, availability, and shipping options.

Let us help you bring this luxury flagship to your country.

A Comprehensive Analysis of the Production Process of Track Roller Professional Manufacturing Creates Outstanding Performance

In the vast system of construction machinery, the track roller is a crucial 'foundation stone' beneath the wheels. As a core component of tracked machinery like excavators and bulldozers, it not only supports the weight of the machinery but also transmits driving force under complex conditions, while enduring various impacts and frictions from the ground. The performance of the track roller is vital for the efficient operation and long-lasting life of construction machinery. Today, we will delve into the manufacturing process behind the scenes, detailing how the production process of the track roller transforms raw materials into a reliable 'companion' of construction machinery.

1. Material selection: laying the foundation for excellent performance

The selection of materials is the first step in the production of track rollers, which directly determines their final performance and service life. In the field of construction machinery parts manufacturing, the commonly used materials of track rollers mainly include alloy structural steel, such as 50Mn, 40Cr, etc.

• 50Mn steel yield strength is more than 645MPa, tensile strength is more than 835MPa, with good strength and wear resistance, suitable for use in medium load and wear environment;

• 40Cr steel after tempering treatment yields a strength is more than 785MPa, tensile strength is more than 980MPa, excellent comprehensive mechanical properties, suitable for bearing large loads and complex stress conditions;

When selecting materials, it is essential to consider not only the material's inherent properties but also the specific application scenarios and operational requirements of the track roller. This ensures that the chosen materials meet the demands for strength, wear resistance, and corrosion resistance. Additionally, the quality inspection of raw materials is crucial, including chemical composition analysis and mechanical performance testing. Only materials that meet the standards can proceed to the subsequent production stages.

2. Casting or forging: shaping the prototype of the Track Roller

According to the structure and performance requirements of the track roller,the casting or forging process can be used to manufacture the blank.

(1) Casting process

For the complex structure of the track roller body, the casting process is usually used. The common casting methods are sand casting and metal casting: (among which, sand casting is divided into artificial sand casting and mechanical sand casting)

• The melting temperature of sand casting is controlled at 1550-1600℃ (carbon steel material), the pouring speed is 5-8kg/s, and the cooling time is set to 4-8 hours according to the size of the workpiece, to ensure that the internal structure of the blank is uniform and there are no obvious defects such as pores and cracks on the surface of the product;

• Metal casting is preheated to 200-300℃ through the mold, which improves the size accuracy of the blank and reduces the surface roughness. The production efficiency is more than 30% higher than that of sand casting.

• Compared with artificial sand casting, mechanical sand casting is more efficient, and the residual sand on the surface of the products after mechanical sand casting is easier to remove; the beauty of the product will also be improved.

(2) Forging process

Forging is a better choice for the track roller shaft that can withstand high load:

• In the process of die forging, the blank is heated to 1150-1200℃ and formed under a press of 8000-10000 tons. The size accuracy of the blank can reach ±0.5mm and the performance can be improved by 20%.

3. Mechanical finishing: give the product a precise size and good performance

After the rough manufacturing is completed, mechanical finishing is required to achieve the dimensional accuracy and surface quality required by the design.

(1) Rough processing

Turning machines, milling machines, and other equipment are used to remove the allowance on the surface of the blank. The allowance for rough machining of the outer circle of the wheel body is 3-5mm, the allowance for the inner hole is 2-3mm, and the allowance for the end face is 1-2mm to ensure the stability of the reference for subsequent finishing.

(2) High-temperature cleaning

• The outer circle of the wheel is cleaned by high-temperature cleaning equipment to wash away the residues left on the surface after rough processing.

• The length of high-temperature cleaning depends on the material, mass, and weight of the track roller.

(3)Modulation processing

• Other manufacturers' roller modulation process is half of the wheel body separately modulation; while our company strictly adopts the whole track roller overall modulation treatment, which makes the track roller always maintain a high level of concentricity value, and thus increases the durability and service life of the product.

• For different products, select different modulation equipment to make the product finish strictly meet the requirements (standard: the surface finish of the track roller is below 3.2).

4. Heat treatment: the key process to improve performance

(1) Annealing and normalizing

The casting blank is annealed at 550-650℃ (holding for 4-6 hours) to eliminate internal stress, reduce the hardness to 180- 220HB, and improve the machining performance; the forging blank is normalized at 900-950℃ (holding for 2-3 hours) to increase the hardness to 220-250HB.

(2) quenching and tempering

• Quenching process heats the parts to 850-880℃ (40Cr steel), keeps it for 1-1.5 hours, and then uses oil cooling or water cooling to cool quickly, so that the surface hardness reaches HRC50-55;

• After quenching, it needs to be tempered at 200℃ for 2 hours to eliminate internal stress and control the final hardness at HRC45-60.

5. Surface treatment: enhance corrosion resistance and wear resistance

Common surface treatment methods and technical parameters:

• Surface quenching: Induction heating temperature 850-900℃, hardened layer depth 2-3mm, surface hardness HRC55-60, suitable for key stressed parts of shaft components.

6. Quality testing: control the product quality throughout the whole process

(1) Raw material testing

• Chemical composition analysis: using a direct reading spectrometer, the detection accuracy reaches 0.01% (such as carbon content detection error ≤±0.005%).

(2) Process detection

• The casting blank must be free of cracks, and burrs and flash must be completely removed. The surface roughness of the product must meet the standard data requirements. In the machining area, defects such as pores, sand holes, and slag must not exceed 1mm in size; for machining areas with a thickness of less than 1mm, the number of defects on one side must be no more than 5 (not concentrated).

• After heat treatment, the Rockwell hardness meter (HRC scale) is used to detect, the sampling rate of each batch is greater than or equal to 5%, and the hardness fluctuation range is less than or equal to ±2HRC.

• Our advantages: In the production of track rollers, after conventional heat treatment, the surface hardness layer of the track rollers will reach 3-4, 4-5, 5-6mm, depending on the machine model. However, ordinary manufacturers only have a thin layer of hardness of about 2mm on the surface, which is more wear-resistant.

Summary: Professional technology to achieve reliable quality

From material selection to quality inspection, every link embodies the professional wisdom and exquisite technology of mechanical manufacturing. The production process of the track roller is complex and rigorous, and each step has an important impact on the performance and quality of finished products.

In the field of construction machinery parts manufacturing, quality control and continuous improvement are the key to the survival and development of enterprises. We always adhere to the strict control of every production link, constantly optimize the process parameters, improve the level of production technology, and devote ourselves to providing customers with high-quality track roller products.

If you have any questions or need information about the production process of the track roller or our products, please feel free to contact us (binochen@yintparts.com) at any time. We will provide you with satisfactory solutions with professional knowledge and quality service. Follow us for more professional knowledge of construction machinery parts manufacturing!